05

2024

-

03

How to improve the various properties of spring steel wire

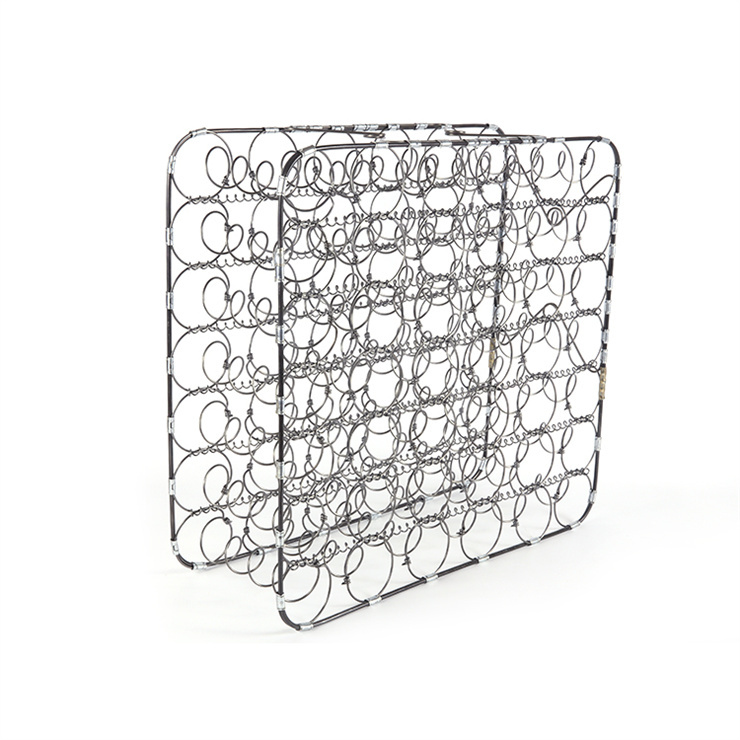

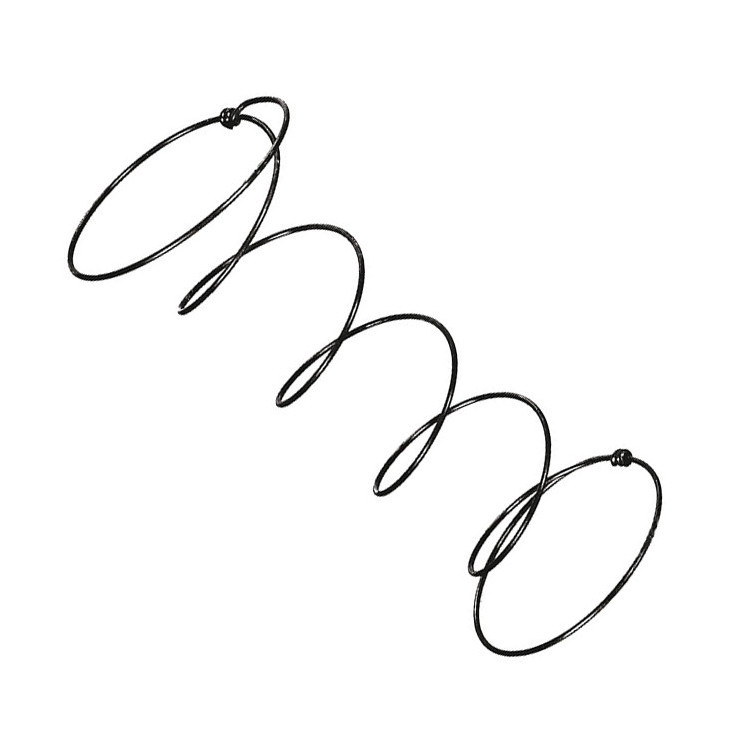

Springs are important components of mechanical power systems, and their performance affects the performance and reliability of the power system. For example, springs used in automobiles and ships have extremely strict working conditions, requiring high stress and dynamic loads, with a fatigue life of over 70 million. Therefore, spring steel wires need to have high tensile strength, fatigue strength, as well as high-quality plasticity and toughness. To meet the above requirements, it is necessary to start from the following aspects:

1. Pre stressing treatment. When the working stress of the spring exceeds its yield stress, in order to effectively reduce the spring stress, it is necessary to pre stress the spring, that is, to cause local plastic deformation in advance. The methods to improve its anti relaxation performance include cold compression treatment, hot compression treatment, rapid compression treatment, electric compression treatment, magnetic field compression treatment, thermal compression treatment, etc.

2. Superfine grain strengthening and toughening treatment. Refining grain size is a means to improve its strength and toughness, which has been applied in spring production. Common methods include rapid heating, cyclic heating, pre cooling deformation, etc.

3. Surface strengthening treatment. Strengthening the surface of the spring is to form residual compressive stress on the surface of the steel wire, which can slow down the speed of fatigue crack propagation. Strengthening the surface of the spring can improve its fatigue life. The methods include ion ammonia infiltration, low-temperature ammonia infiltration, etc.

Noticias relacionadas