PRODUCT

Contact Us

Phone: +86-0539-8228838

Wechat: 18253974567

Whatsapp: +8618253974567

E-mail: jack@jlfmcl.com

Address : Luozhuang district.Linyicity Shandong Province,China

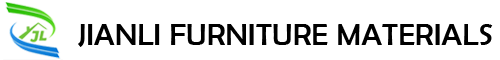

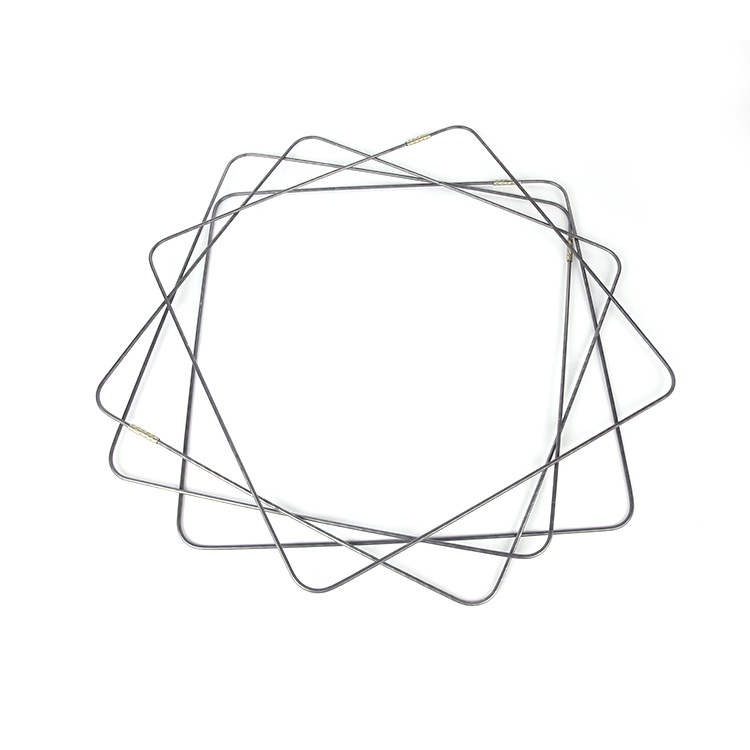

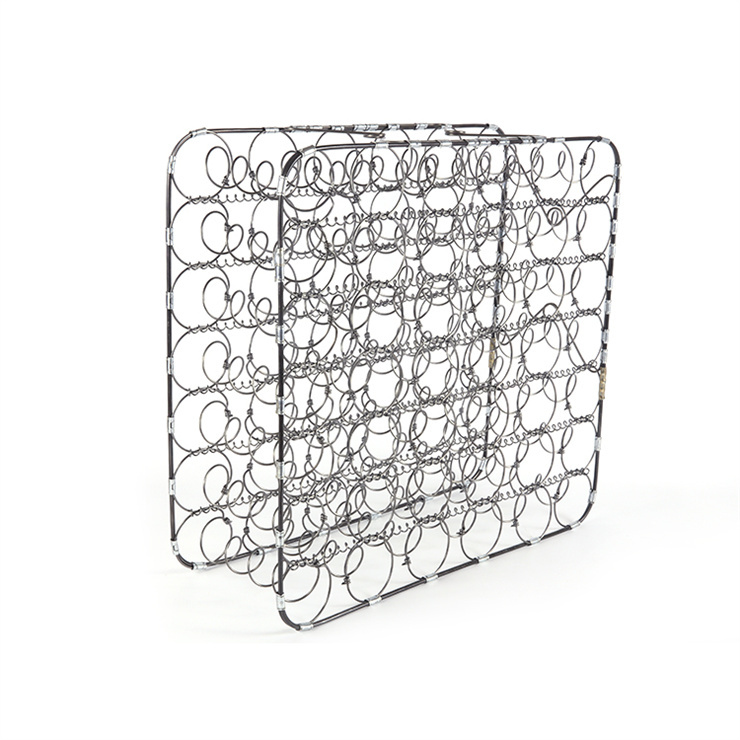

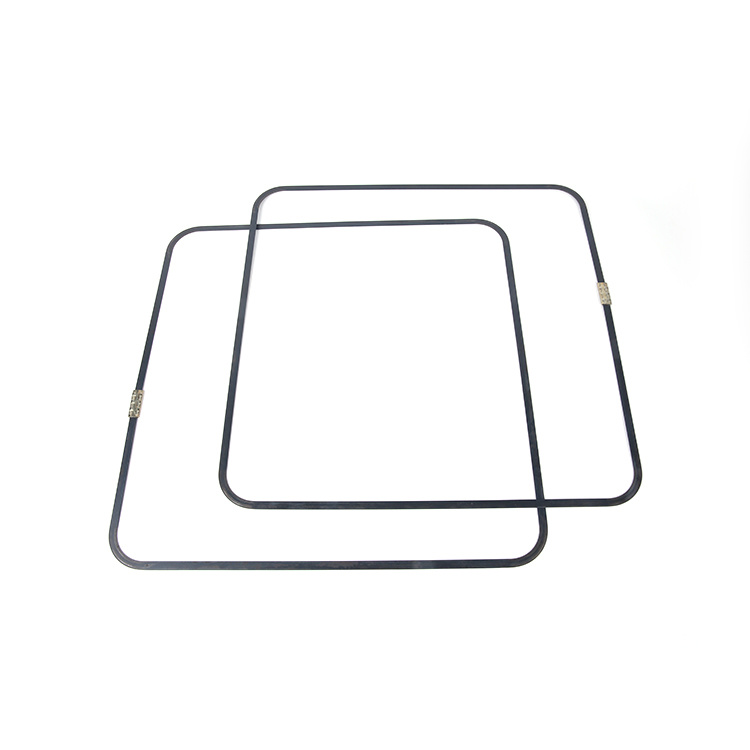

Coil package frame for mattress

Wire diameter:1-5 mm/ 1.5*10 mm

Application:High elasticity for roll mattress

Classification:

keyword:

Coil package frame for mattress

Whatsapp:

E-mail:

Message

DESCRIPTION

Excellent material selection

The product materials are all made of high-quality materials, which are harder than ordinary materials, not easy to get wet, and not easy to rust.

Custom processing

Product specifications are diverse, and can also be customized for processing and production according to needs.

Material

65MN/72B/77B/82B

Size

88*188, 118*188, 135*188, 150*196, 180*196, 950*1920, 1200*1920, 1380*1920, 1520*1920, 1770*1970, 1470*1970, 1170*1970, 1840*1640, 1840*1340

Wire diameter

1-5 mm/ 1.5*10 mm

Product paramenters

|

Item

|

Value

|

|

Model Number

|

mattress flat border frame

|

|

Material

|

65MN/72B/77B/82B |

|

Product name

|

spring steel frame for mattress

|

|

Raw material

|

65MN

|

|

Production diameter:

|

1.5×10mm

|

|

Production reduction

|

Generally 30mm in length and width

|

|

Four corners R arc

|

35mm

|

|

MOQ

|

1Metric tons

|

|

Take over

|

On W, the center point of the nozzle is 9-35cm away from the L side, the length of the nozzle is 40mm±2mm, and the inner diameter of the nozzle is greater than or equal to the steel wire diameter of 0.5mm

|

|

Cross value (diagonal)

|

≤25mm

|

|

L/W Actual production error

|

±2mm

|

|

Application

|

High elasticity for roll mattress

|

|

Packing

|

Galvanized iron wire binding, four - corner woven bag packaging40/50 pieces a handful (bound with galvanized iron wire, packed in woven bag), 1000 pieces in a large bag

|

Packaging display

Pre

Siguiente

GLOBAL COOPERATION

Customer photos

Customer photos

Customer photos

Customer photos

CERTIFICATE

Honor

Honor

Honor

Honor

RELATED PRODUCTS

FAQ

What are the commonly used production methods for various spring steel wires?

(Steel) Wire rod - Surface treatment - Drawing (This method can be used for mattress steel wire)

How to treat the surface of spring steel wire?

Generally, acid pickling and phosphating are used to remove iron oxide scale and form a phosphating film; There are also a few who use mechanical methods for processing. The purpose is to meet the requirements of the cold drawing process and obtain a smooth surface. For spring steel wires that require high fatigue life, such as valve spring steel wires, the coil should be peeled to reduce surface defects. If the steel plant can grind the steel billet, it is also beneficial to reduce defects.

How to wire draw the spring steel wire?

The drawing process of finished products has a significant impact on product performance. Generally, a larger total reduction rate of about 90% (see area reduction rate) and a smaller pass reduction rate (about 10% -20%) are used to ensure the toughness of the product. For high-strength spring steel wire, the outlet temperature of each pass of steel wire should be controlled below 150 ℃ during drawing to prevent torsion cracks caused by strain aging, which is the main defect causing steel wire scrap. Therefore, good lubrication and sufficient cooling are necessary during drawing, and using smaller pass reduction rates and drawing speeds can help reduce the temperature rise of the steel wire.

Production process of spring steel wire for beds

1. When selecting raw materials, consideration should be given to their tensile strength and torsional performance, and torsional tests should be conducted to ensure that the raw materials do not crack and the surface is flat. 2. During heat treatment, decarburization of the raw materials should be avoided to ensure a high carbon content and obtain a more stable sorbite structure. 3. When drawing semi-finished products, a process with high compression rate, multiple passes, and a small portion of compression rate should be adopted, as well as a reasonable drawing route. During the drawing process, the drawing equipment, lubrication and cooling conditions, and mold dimensions must be strictly followed according to the standards to ensure the flatness of the finished product. 4. Develop a reasonable immersion temperature to ensure that the product is time sensitive.