05

2024

-

03

The Effect of Heat Treatment on Steel Wire Structure

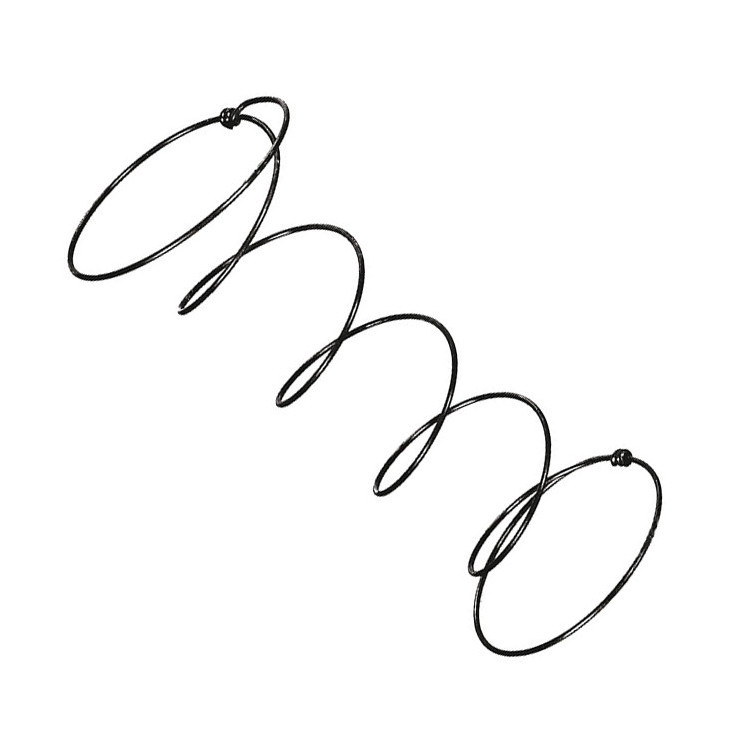

In order to obtain higher elasticity, the steel wire is quenched and tempered during heat treatment to obtain the austenite structure. The selection of quenching temperature should ensure obtaining austenite while maintaining grain refinement and improving the impact value of the steel wire. According to research, when the austenite temperature is below 850 degrees, there are undissolved carbides in the steel structure. As the temperature increases, the amount of undissolved carbon decreases. It can be seen that the better quenching temperature during heat treatment is 900 degrees.

The characteristics of spring steel wire after quenching and heat treatment are fast heating speed, refined austenite, with an average austenite grain diameter of d=12Lm and a grain size of more than 10 levels, which is finer than that obtained by ordinary heating method with an austenite diameter of d=22Lm and a grain size of 8 levels. Moreover, the toughness and strength of the steel wire treated by this method have significantly increased.

Noticias relacionadas