05

2024

-

03

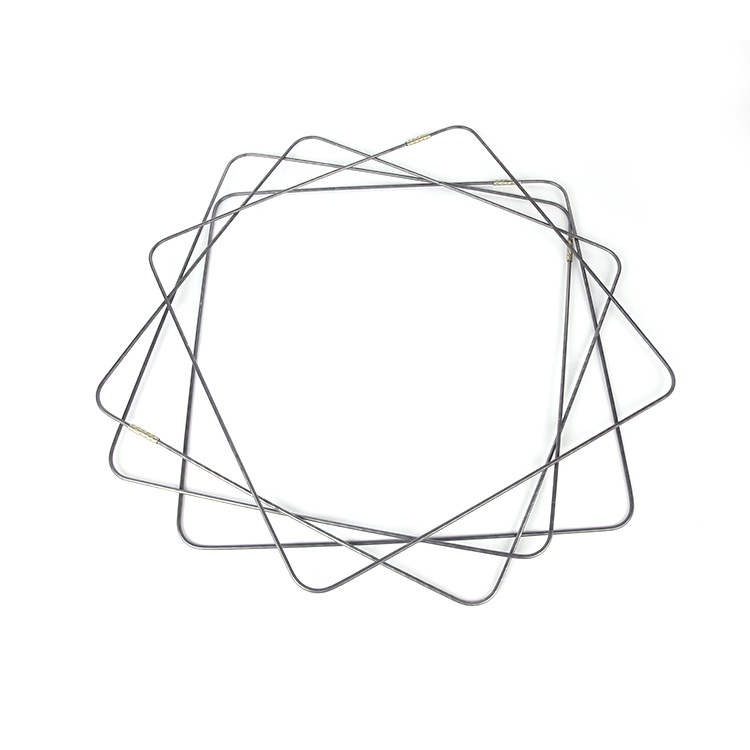

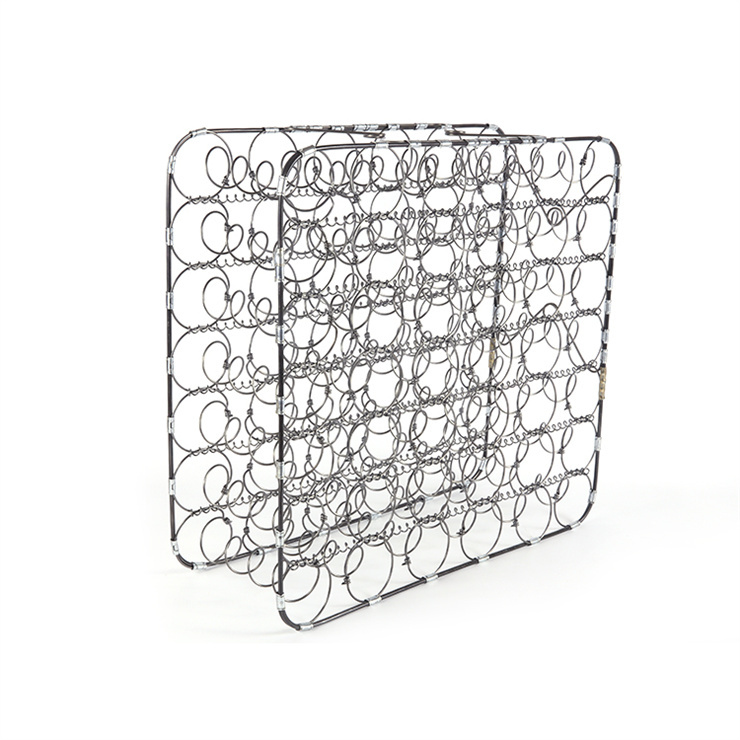

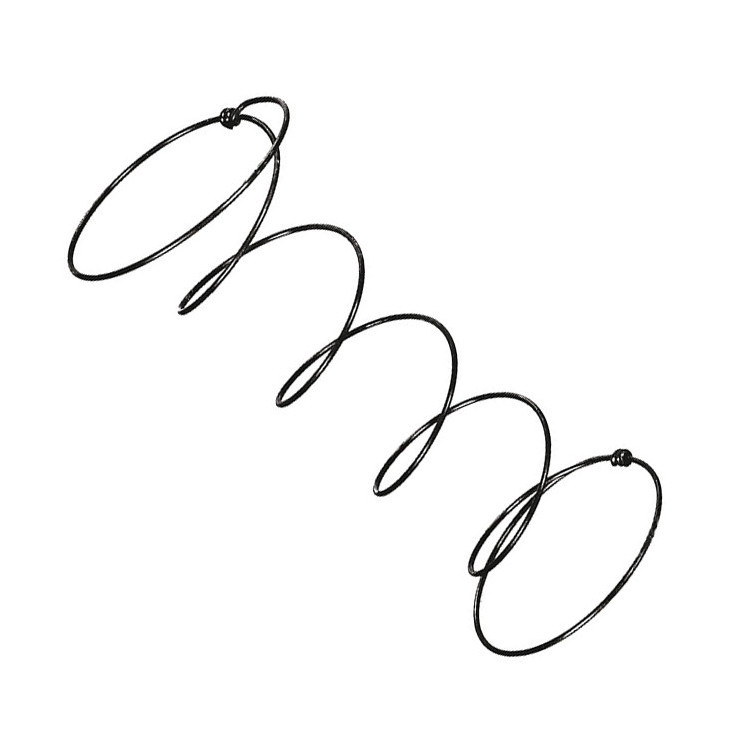

Mesh wire can be applied in the production of sanitary ceramics

In the production of ceramics, screening methods are often used to control the quality of mud. The quality of the screen directly affects the product quality. In the production of sanitary ceramics, the screen is both a production tool and a testing tool. As a production tool, it needs to meet the following aspects:

1. Separate particles of different sizes through a sieve;

2. Screen out unnecessary large and small particles to ensure that the particle size and fineness of the material meet the product requirements;

3. During the processing, timely separation of qualified materials can improve processing efficiency;

4. As an auxiliary means of mud purification, it can remove impurities from the mud.

When used as a detection tool, the screen mainly includes the following aspects:

1. Check if the fineness of the mud is qualified; Beneficial for accurate control;

2. Check whether the fineness of the purchased raw materials is qualified;

3. Classify and screen the raw materials;

A qualified sieve depends on the selection of sieve mesh, which requires the production of sieve mesh with consistent mesh size, horizontal and vertical mesh lines, and the screening of particles with the same particle size during production to ensure the production of high-quality and reliable products.

Noticias relacionadas