05

2024

-

03

How to avoid the occurrence of pitting during spring production process

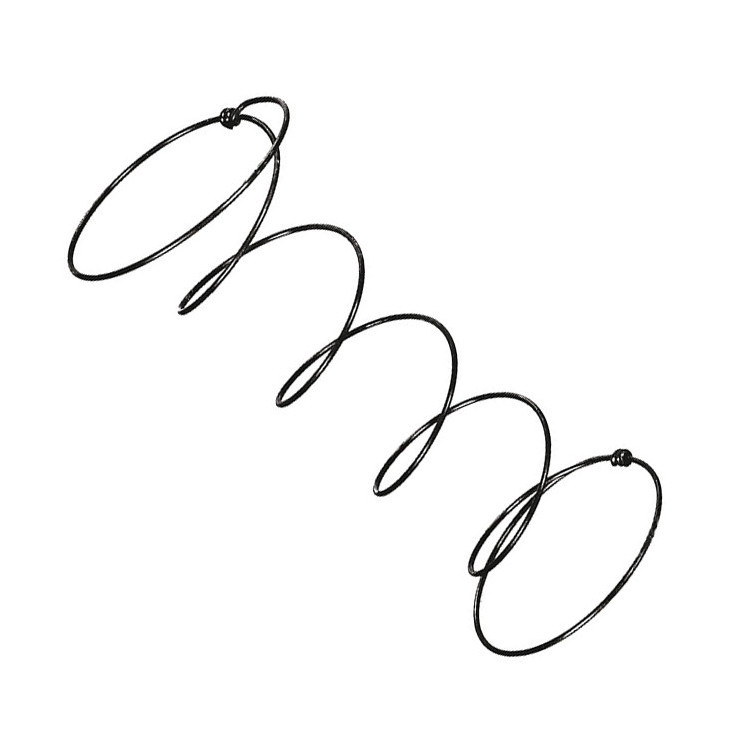

Improper operation during the production process of springs can easily produce pitting, making the product surface rough and affecting product quality. These spots vary in size and distribution. The occurrence of general pitting is caused by the steel during the extrusion process. When pitting occurs, the extrusion speed should be adjusted in a timely manner to avoid more pitting.

1. The impact of excessive impurities in raw materials. There are too many non-metallic impurities in the raw materials. Due to the large particle size of non-metallic impurities and the lack of stable crystalline structure in the material, defects are prone to occur during the oxidation coating of steel, and in severe cases, pitting may occur;

2. Excessive force during the squeezing process. In order to achieve the squeezing effect, different types of tools are generally used to squeeze the steel wire. The fit between the squeezing pad and the squeezing cylinder is also the reason for the appearance of pitting in the product, which reduces the performance and appearance smoothness of the product.

Noticias relacionadas