05

2024

-

03

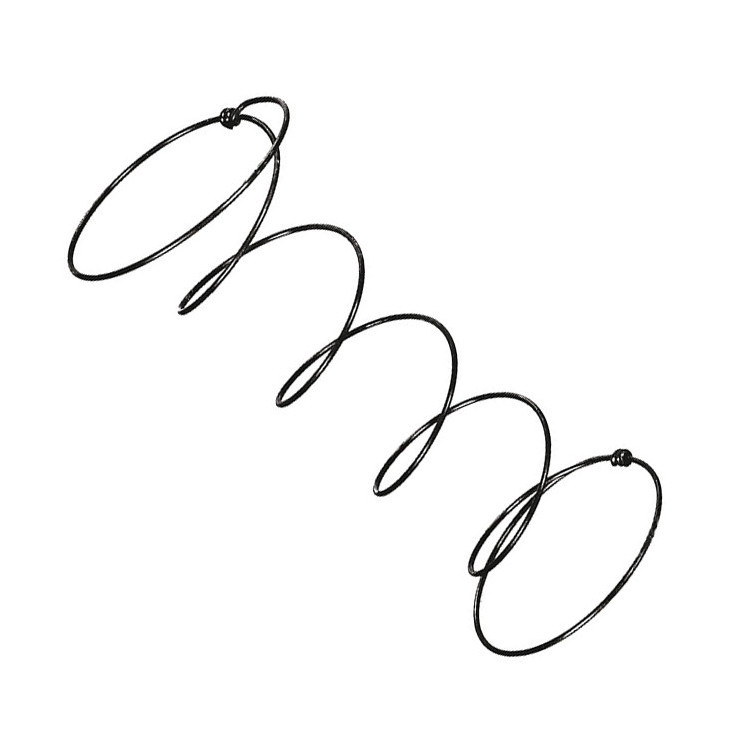

What phenomena affect the toughness of products during the processing of spring steel wires

The processing process of spring steel wire is long and complex, and improper operation in each process can have an impact. Haoxin Steel Wire has many years of practical experience in processing and production, and we have summarized the following factors that affect the toughness of steel wire:

1. The toughness of spring steel wire depends on the lead quenching process and the obtained martensite structure. The fine-grained martensite structure can withstand severe deformation. During the drawing process of the steel wire, the martensite is extended and close to each other. By adjusting different heat treatment processes, the martensite is uniformly refined, thereby improving the twisting ability.

2. During the heating process of steel wires, when the temperature exceeds 200 degrees, the toughness decreases. In high temperature seasons, it is necessary to reduce the heating temperature to improve product quality.

3. During the production process, the influence of residual stress on spring steel wire should be improved, and measures should be taken to reduce or reverse pulling. The wire drawing die should be selected to ensure lubrication conditions, thereby reducing the influence of residual stress and ensuring the toughness of the product.

4. The anti rust temperature of the finished product should not exceed 10 degrees. After the spring steel wire has oil seepage, it should be coated with oil at room temperature to ensure that it does not affect the toughness of the steel wire.。

Noticias relacionadas